Protecting a cutting-edge pharmaceutical production plant with reliable and modular fire detection

Fire safety at a leading Cipla manufacturing facility was upgraded to highly reliable customized solutions and remote services from Bosch.

Summary

Project

Manufacturing plants

Cipla Limited pharmaceutical manufacturing plant

Benefits

- Modernization of fire alarm system

- Adaptable, customized and scalable solution

- Future-proof networks and connectivity

- Remote monitoring and maintenance

- Intuituive user intefaces for safety managers

Product solutions

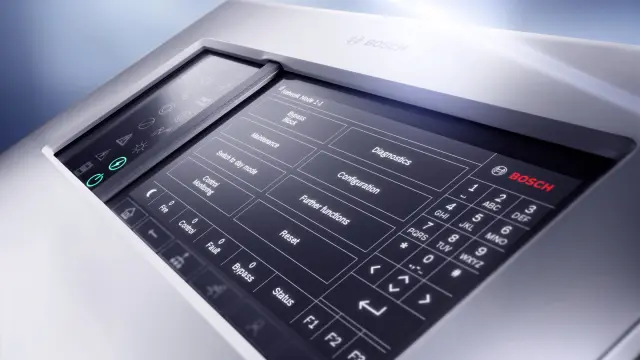

- AVENAR 8000 fire alarm panels

- AVENAR 4000 multi-sensor detectors

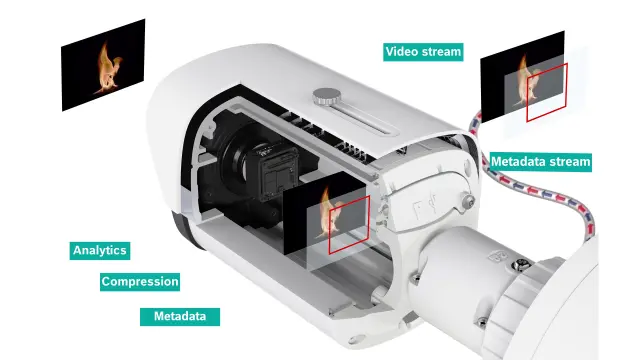

- AVIOTEC video-based fire detection

- Explosion-proof detectors

- Remote services

Cipla Limited is an Indian multinational pharmaceuticals firm. The company was first established in 1935 as the Chemical, Industrial and Pharmaceuticals Laboratories in Mumbai. The core focus of Cipla’s business is to develop effective treatments for respiratory and cardiovascular diseases, diabetes and numerous other medical conditions. It is one of the world’s largest manufacturers of antiretroviral medications. The company has extended its presence to over 80 countries and provides over 1,500 products across various therapeutic categories. Cipla regularly gains recognition for drug formulation breakthroughs and state-of-the-art manufacturing, and wins awards for digital customer service functionality and efforts towards ESG. As a pioneer in the pharma industry, Cipla recognized the need to upgrade the company’s fire safety systems at its manufacturing site in Patalganga, Maharashtra, in line with the innovative solutions currently available.

The fire alarm panels at the Patalganga location had been installed quite some time back and there was a need to replace the same considering the latest innovations in the Fire Alarm Industry. It was recognized that the fire detection and alarm facilities needed an urgent upgrade to ensure reliability, however, selecting a replacement to serve the vast manufacturing site was not a simple process. Cipla’s safety managers had decided that maintaining the original network cable was preferred over laying a whole new network. This meant that any new fire alarm system under consideration had to be integrated and adapted to the existing infrastructure and needed to be scalable and future-proof.

In addition, the distance between some sections of the plant spans up to three kilometers. The safety managers wanted to reduce cabling to cover these distances and to explore options which allowed for numerous fire detection devices to be installed within each single loop. Furthermore, although the entire site required fire safety coverage, some facilities were more critical and thus demanded early smoke and flame detection. For alerts with sounders and strobes, the team requested a solution that could be powered directly within the loop, rather than employing external power sources.

A comprehensive, high-capacity fire detection system was required to precisely monitor for signs of ignition or combustion for a rapid response and to avoid unnecessary downtime. The safety team at Cipla also requested a dashboard-style interface for efficient troubleshooting and to identify priorities of maintenance requirements. The first step was to elevate the existing setup into the digital age to improve accuracy, transparency and system care.

Contact us

Do you want to learn more about our fire detection systems for manufacturing plants? Just fill in the contact form and we will get back to you.